A senior manager at a large cereal factory has praised Summit Power’s emergency power response after an outage at the facility brought production to a halt.

The failure of the site’s low voltage (LV) switchgear resulted in a total blackout, stopping manufacturing processes across the entire plant.

Responding swiftly to an urgent call received at 2pm, Summit Power mobilised a temporary power solution that was on-site by 9am the next morning.

Within 24 hours, the Summit Power team had installed a robust system to restore power, allowing production to resume.

Power Solution, Tailored and Timely

Summit Power delivered a 2MVA temporary power solution, installing four 500kVA Stage V generators in a smart load-on-demand configuration.

This optimised generator efficiency and reduced fuel consumption during periods of low load, significantly lowering the client’s operational costs and the solution’s carbon footprint.

Supporting the Stage V generators, we also mobilised 18,000 litres of fuel storage and 6,000 litres of AdBlue, ensuring a steady supply throughout the duration of the hire.

The engineering and application design were completed quickly and remotely, allowing the correct equipment and configuration to be installed seamlessly once the equipment was delivered to the site.

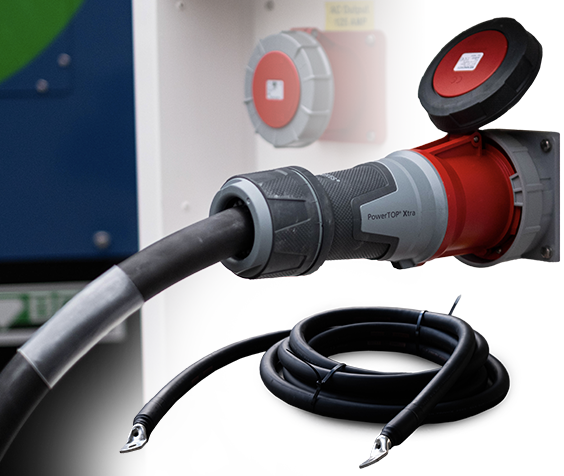

Despite the complex site requirements, Summit Power’s expert team swiftly installed 1,800 metres of 240mm cable in just 24 hours, seamlessly distributing power across the factory to resume operations as quickly and safely as possible.

“Summit Power’s rapid response was crucial,” said the site manager at the facility. “Its team’s ability to get our factory back up and running within 24 hours helped us avoid what could have been a major disruption to our production schedule. The tailored power solution met our immediate needs and also provided cost savings we hadn’t anticipated.”

“Summit Power’s rapid response was crucial,” said the site manager at the facility

Minimising Disruption in Manufacturing and Production

For a manufacturing plant, any period of downtime can lead to significant losses.

Summit Power’s emergency response put in place a temporary power solution in under 24 hours and also ensured ongoing support throughout the four-week hire duration.

Also, Summit Power’s fuel management services were integral to the plant’s operation, with remote monitoring installed on the fuel tanks providing visibility that ensured fuel deliveries were timely and of the correct quantity. This proactive approach allowed production to keep going smoothly and avoid any interruptions.

Throughout the contract, Summit Power ensured reliable continuation of power and performed equipment maintenance with no disruption to the factory’s production operations, due to the well-planned application design.

The rapid intervention and support allowed the cereal factory to continue meeting its production targets while permanent repairs were completed.